It all started from curiosity.

About 70 years ago.

After WWII, when Japan started to follow foreign trends,

there was a young man interested in fashion who sold hats in department stores.

The young man thought imported hats were too expensive for ordinary people,

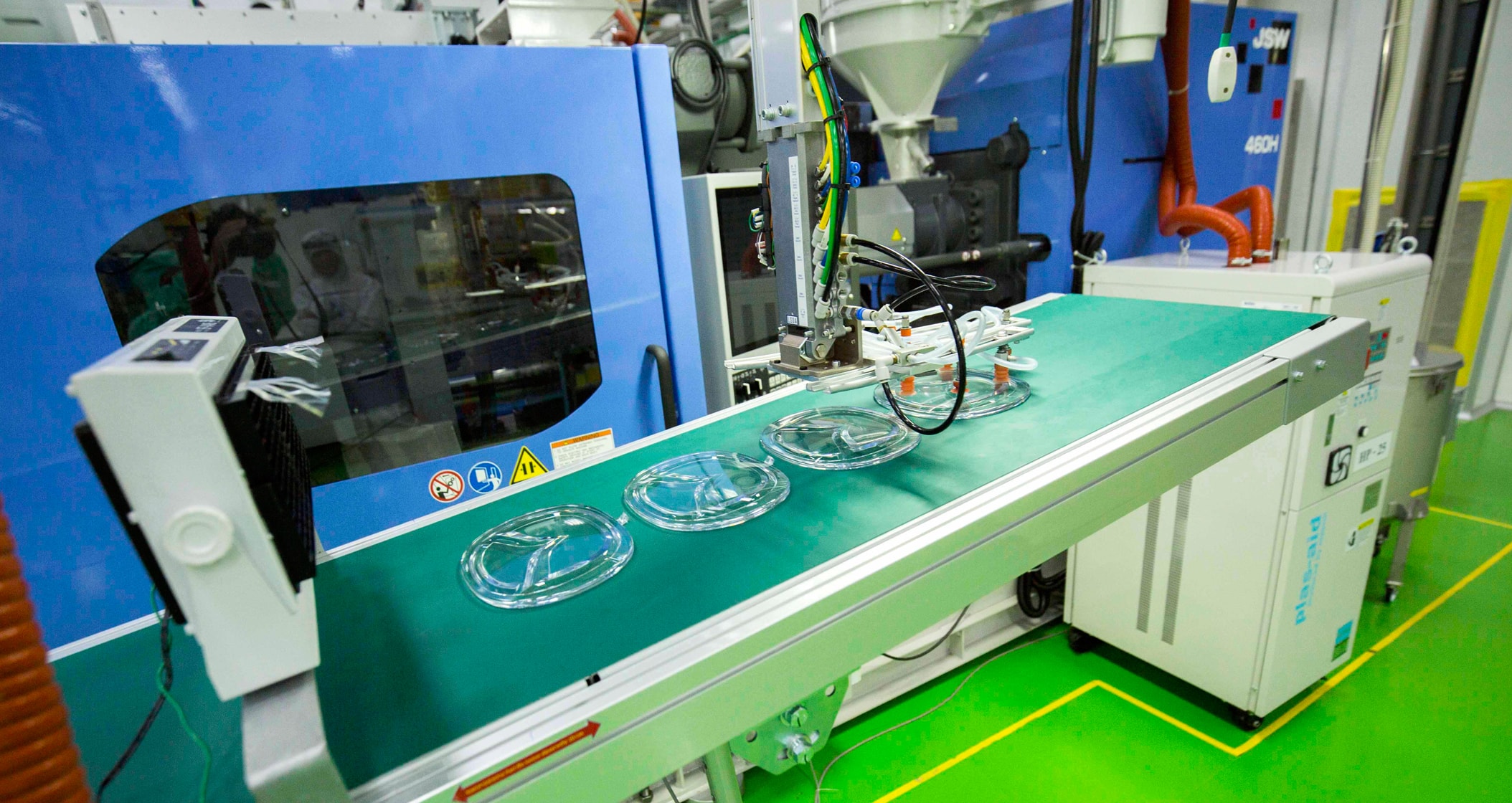

so he decided to learn press technology to create cheaper hats by himself.

At the time, hats were made by covering wooden models with fabric,

steaming it, and applying pressure with a sandbag.

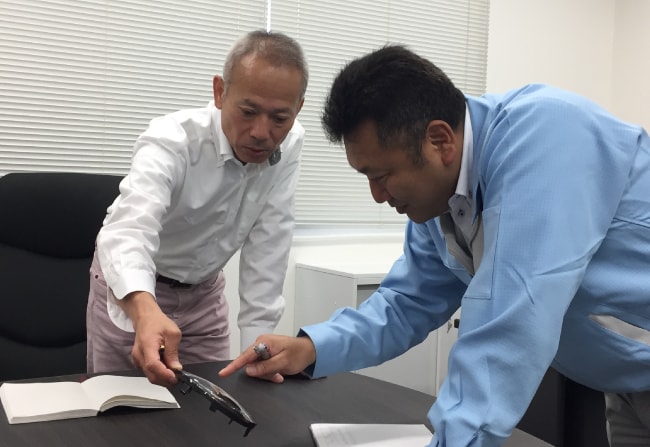

While working as a salesman and engineer at "Ohya Nameplate",

the young man was wondering if he could apply this press technology to create something else.

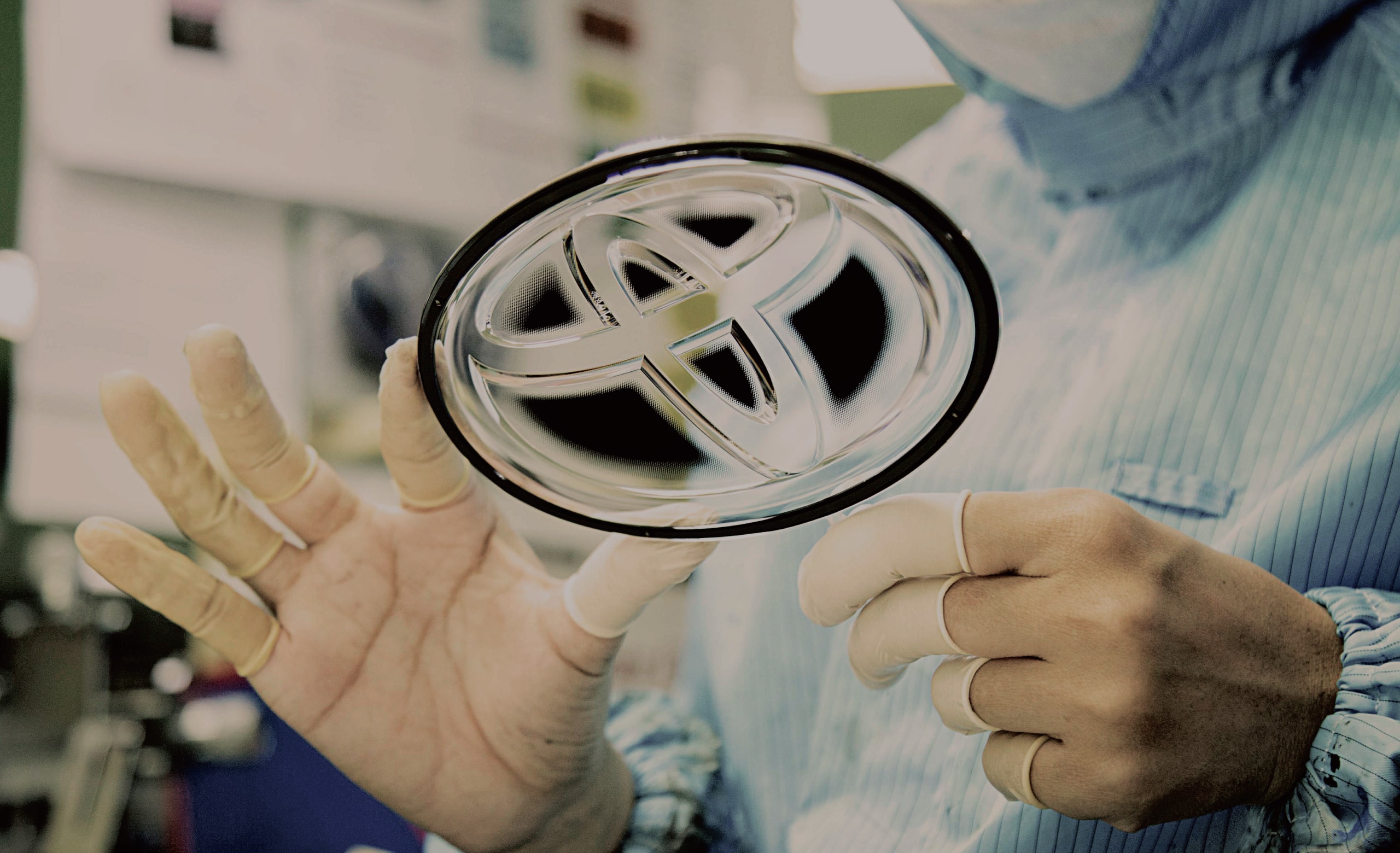

Shinko Nameplate Co. Ltd

Shinko Nameplate Co. Ltd  Struggling with adversity,

Struggling with adversity,  What metal can do,

What metal can do,  As light and thin as possible.

As light and thin as possible. Looking ahead of the future,

Looking ahead of the future,  Emblems became

Emblems became  Pursuing technology

Pursuing technology